Ferroresonant Transformer Manufacturing

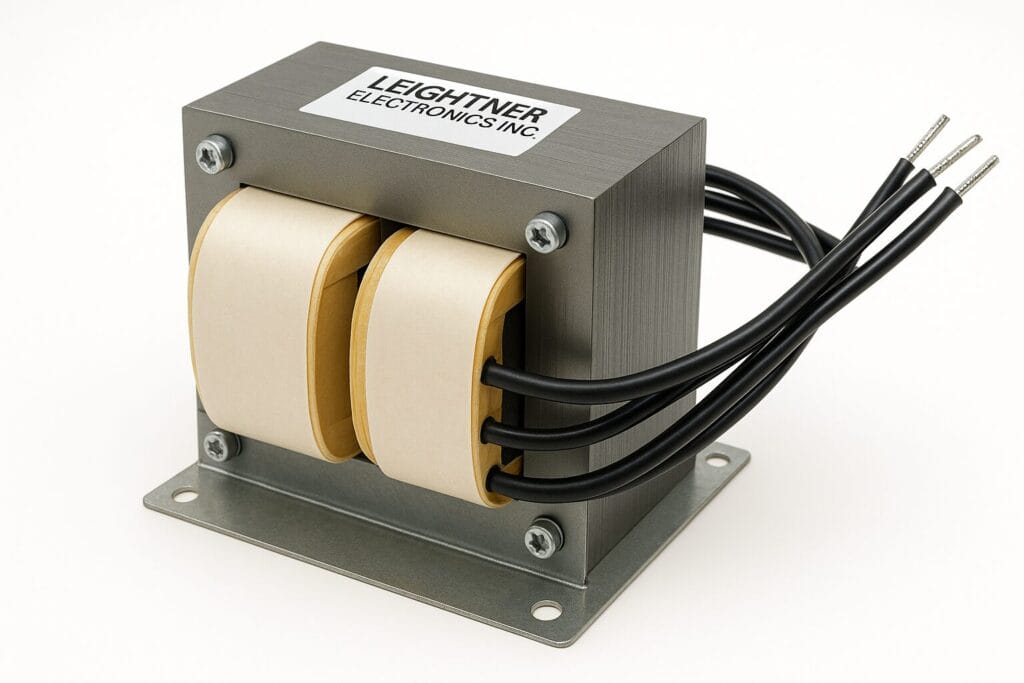

Custom Ferroresonant Transformer Manufacturer

To suit your unique application requirements, Leightner Electronics designs custom ferroresonant transformers (constant-voltage transformers) to your specifications. All unique ferroresonant transformers are engineered and manufactured in-house at our facility in McKinney, Texas, where we also maintain full control over all engineering, prototyping, design and development. To find out how Leightner may help your transformer needs, call 972-542-0176 or contact us!

Ferroresonant Transformer Benefits & Advantages

Ferroresonant transformers, also known as constant voltage transformers (CVTs), offer several significant advantages in power supply applications:

- Voltage Regulation and Stability

- Protection and Isolation

- Current Limiting and Self-Regulation

- Reliability and Durability

- Power Quality Improvement

Ferroresonant transformers offer a combination of voltage regulation, protection, reliability, and power quality improvement, making them valuable in applications requiring stable and clean power supply, particularly in industrial and critical infrastructure settings.

Custom Ferroresonant Transformers Tailored to Your Requirements

Ferroresonant transformers can be tailored to suit almost any need by Leightner Electronics. Whether you need a simple design or a complex setup, we can make a transformer to fit your needs. Our design for your needs will vary on a few factors:

- Power Rating: Typically ranges from 50 VA to 10 kVA for single-phase designs, with some clients needing support for three-phase configurations.

- Input Voltage Range: Standard: ±15–25% of nominal voltage. Extended: Up to ±40% for specialized designs, enabling operation in extreme grid conditions.

- Output Voltage Regulation: Standard: ±1–3% under load, even with input fluctuations. High-Precision: Controlled designs with electronic regulation achieve ±0.5% accuracy.

- Frequency: Primarily 50/60 Hz, with custom designs available for 400 Hz (aviation) or 20 kHz (high-frequency applications).

- Efficiency: Single-phase: ~75% Three-phase: ~85%.

- Surge Protection: Attenuates transients up to 6 kV and filters line noise.

- Waveform Output: Quasi-square wave: Reduces DC filtering needs. Low-distortion sine wave: <3% THD under load.

- Temperature Tolerance: Operates reliably from -40°C to +85°C with optional thermal monitoring (RTDs or thermocouples).

Ferroresonant Transformer Manufacturing Process

Applications for Ferroresonant Transformers

Ferroresonant transformers have several important applications across various industries due to their unique voltage regulation and power conditioning capabilities:

- Power Supply for Critical Equipment

- Manufacturing and Production

- Oil and Gas Industry

- Petrochemical Industry

- Power Generation Facilities

- Pipeline and Transmission Systems

- Power Quality Improvement

Let Leightner Design Your Ferroresonant Transformer Today

With over 50 years of manufacturing and hundreds of thousands of transformers built to specifications, Leightner can handle any application of your custom Ferroresonant transformer needs. Request a quote to start the manufacturing process today!

Contact Us Today For Your Custom Transformer Needs

Leightner has over 50 Years of Experience Prototyping, Designing, & Manufacturing Custom Transformers For All Types of Applications