Custom Toroidal Transformers

Custom Toroidal Transformer Manufacturing

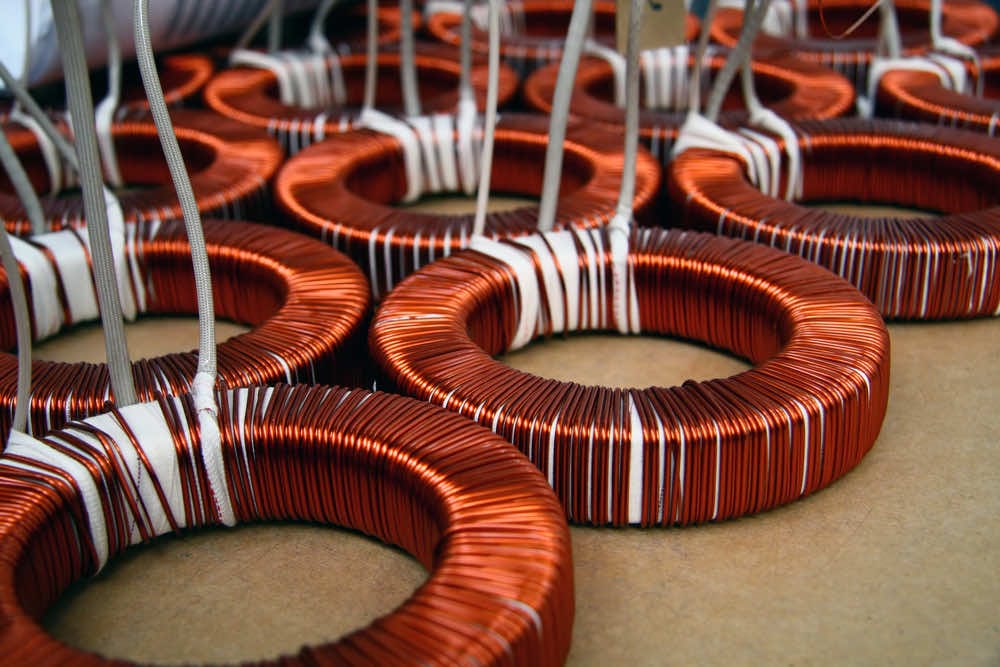

A toroidal transformer is a unique and efficient type of electrical transformer that utilizes a ring-shaped core, giving it its distinctive doughnut-like appearance. The core of a toroidal transformer is made from a continuous strip of grain-oriented silicon steel tape, wound in a circular shape. This tape is typically coated with an insulating material to prevent eddy currents. The primary and secondary windings are then wound around this ring-shaped core, distributed evenly to cover its entire circumference. This design offers several advantages over traditional laminated core transformers, making toroidal transformers popular in various applications.

Custom toroidal transformer manufacturing involves specialized design and production processes to meet precise application requirements, leveraging unique core materials and advanced winding techniques. These transformers are prized for their compact size, high efficiency, and low electromagnetic interference (EMI), making them ideal for industries like medical devices, renewable energy, audio systems, avionics and telecommunications.

Toroidal Power Transformer Advantages

Toroidal power transformers offer several significant advantages over traditional EI (Electromagnetic Interference) transformers, making them a popular choice in various applications. Here are the key benefits of using toroidal transformers.

- Efficiency and Performance: Toroidal transformers are known for their high efficiency, typically ranging from 95% to 99%. This superior efficiency is due to their unique circular design.

- Size & Weight: Half the size and weight of traditional transformers, allows for the same power output in a smaller package, fewer raw materials

- Noise Reduction:Toroidal transformers are known for their quiet operation: lack of mechanical hum, absence of air gaps in toroidal cores helps reduce noise issues

- Electromagnetic Interference (EMI): Toroidal transformers excel in minimizing EMI: produce significantly less stray magnetic energy, magnetic flux is largely contained due to the configuration of windings and core, making toroidal transformers ideal for in electronic devices with delicate components.

- Mounting and Installation: Toroidal transformers offer convenient mounting options: often be mounted with just one bolt, compared to four or more for laminated EI transformers, lowering maintenance and downtime.

- Thermal Performance: Toroidal transformers have better thermal characteristics: operating at lower temperatures, circular shape enables more uniform heat distribution, preventing hotspots

- Cost-Effectiveness: Despite potentially higher initial costs, toroidal transformers can be more economical in the long run: high efficiency leads to long-term cost savings due to lower energy consumption, compact size can reduce overall system costs by allowing for smaller chassis designs.

Toroidal Power Transformer Manufacturing Process

Applications of Toroidal Power Transformers

Toroidal power transformers offer significant advantages in terms of efficiency, size, and performance across a diverse range of applications. Their unique design makes them particularly well-suited for situations where space is limited, noise reduction is crucial, and high efficiency is required.

- Industrial Applications

- Power Supply and Distribution

- Consumer Electronics

- Medical Devices

- Renewable Energy Systems

- Specialized Equipment

- Audio Equipment

Design Considerations for Custom Toroidal Transformers

Leightner designs custom toroids for specific applications. A custom toroidal transformer requires careful attention to various factors to ensure optimal performance, efficiency, and reliability for your application. These vary by your specifications for power output requirements, maximum voltages, currents, and frequencies needed. Other considerations for your toroidal designs include:

- 1. Core Material Selection

- 2. Winding Configuration

- 3. Efficiency and Loss Minimization

- 4. Electromagnetic Interference (EMI)

- 5. Thermal Management

- 6. Mechanical Design (size)

- 7. Application-Specific Customization

- Define key specifications such as power rating, voltage, current, frequency, duty cycle, and environmental conditions.

- 8. Compliance with Standards

Let Leightner Design Your Toroidal Transformers Today

With over 50 years of manufacturing and 100s of 1,000s transformers built to specifications, Leightner can handle any applications of your custom toroidal transformer needs. Request a quote to start the manufacturing process today!

Contact Us Today For Your Custom Transformer Needs

Leightner has over 50 Years of Experience Prototyping, Designing, & Manufacturing Custom Transformers For All Types of Applications